CNC Tube/Pipe Bending & Fabrication

Tube & Pipe Bending Solutions

Custom Marine specializes in bending stainless steel, titanium, aluminum and a wide variety of other materials. We create precise tube within a tube bends for our customers to use in different water-jacketed applications.

- CNC Mandrel bending

- Multiple CLR Stack bending capabilities

- Tube within a Tube Bends and Assembly

- Complex Tube Fabrication

- Diameters: ¾″ to 6″ diameter

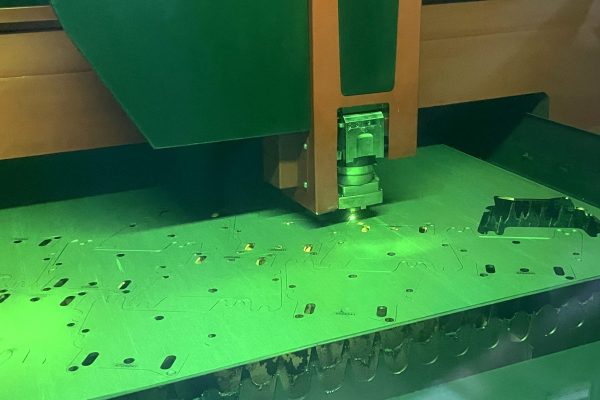

Laser Cutting & Water Jet

Precision Laser Cutting

For sheet metal processing, our team has you covered. The Bystronic BySmart Fiber Optic Laser 3015 can accommodate sheet sizes up to 118″ X 60″.

- 6,000 Watt Power head

- Cuts up to 1″ thick stainless steel

- Table size 5 ft by 10 ft

5-Axis Water Jet Cutting

Custom Marine uses the flagship model WARDJet Z-2543, featuring modular design and the flexibility to cut a large array of materials.

- No heat-affected zones

- Tight tolerances can be held

- Nesting software available

- Minimal fixturing for quicker set-ups

- Burr-free end product

- Cuts up to 8″ thick steel

Tube End Forming

With Custom Marine, precision tube end forming can be accomplished through single or multiple hit end forming or rotary forming devices on small-to-large diameters.

MULTIPLE HIT END FORMING

- Offset Expand

- Coping

- Piercing

- Tube Reducing

- Swaging

- Punch holes and slots

- Beading

- Flaring

- Expanding and Stamping

- Square, rectangle, oval, round tubes, or any specialty shape

ROTARY FORMING

- Beading

- Flaring

- Knurling

- Inverted Bead

- Finish Cut After Bend

- OD Grooving and Hose Barb

TUBE EXPANSION

- Small to large diameter

Don’t see what you want? Send us your print for a custom quote!

Get StartedMachining

CNC Machining Solutions

Custom Marine has a complete in-house machine shop dedicated to developing tooling, fixtures and components necessary for prototype or full production. This adds to a full array of support services and capabilities that enables Custom Marine to deliver specific components or a complete system solution for any application.

- CNC Lathes with Bar feeders

- CNC Vertical Milling

- CNC Horizontal Milling

- Manual Mill and Lathe

- Tornos Swiss GT

- Star CNC Swiss-type Automatic Lathe

- Mitsubishi Wire EDM

- Fanuc Robocut Wire EDM

- Mastercam CAD/CAM Software

- Tool and Die design and fabrication

Robotic & Manual Welding

Welding Capabilities

Custom Marine’s fabrication experts have many years of precision welding experience using state-of-the-art manual and automated welding equipment.

- ABB Robots

- Complete in-house design and fixturing capabilities

- Mig, Tig and Plasma capabilities

- Commonly used materials: stainless steel, aluminum, titanium, etc.

Metal Finishing and Polishing

Custom Marine has the ability to deliver your product with the best finish suited for your application, from raw to full polish. These different finishes are accomplished through manual and/or automated processes.

ROBOTIC POLISHING

Robotic polishing offers a significant savings on material consumption, with the capacity to work 100% autonomously. It also provides greater consistency in your product and speeds up the cycle time. Our robotic systems feature an automatic working pressure control system, for a quality product every time.

SHEET POLISHING

Custom Marine’s metal working machines provide solutions for a variety of applications, including deburring, graining, finishing, edge radiusing, oxide removal, grinding and dimensioning. We use the Apex 2000 Series Wet Metal Machine and Timesaver Puma 52MWT-DDDB-75 built for heavy production and designed to run multiple shifts each day.

- Vibratory Polish and Burnishing

- Manual Polish

- Centerless grinders up to 8″ diameter tube

- Glaser elbow grinding machines

- Rough, Satin or Mirror finishes

EDGE ROUNDING

The Loewer Innovative DiscMaster 4TD can handle edge rounding and orbital finishing in just one pass, processing steel, stainless steel and aluminum.

- Deburring and edge rounding laser-cut, plasma-cut and water-cut parts

- Processing small parts from 20mm by 20mm

Press Brake

Metal Sheet Forming

Whatever your application, Custom Marine uses press brake systems to form sheet metal to your exact specifications. We offer a full library of in-house tooling, using the powerful Trumpf Press Brake. High tonnage means we can take on larger projects, and you get the quality product your customers expect.

- Tonnage: 95 tons

- Overall length: 106″

- Distance between columns: 88″

- Stroke: 20″

- Throat: 16.5″

- 6-axis back gauge