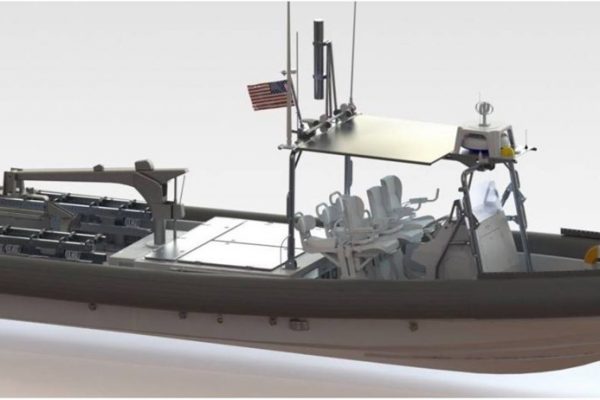

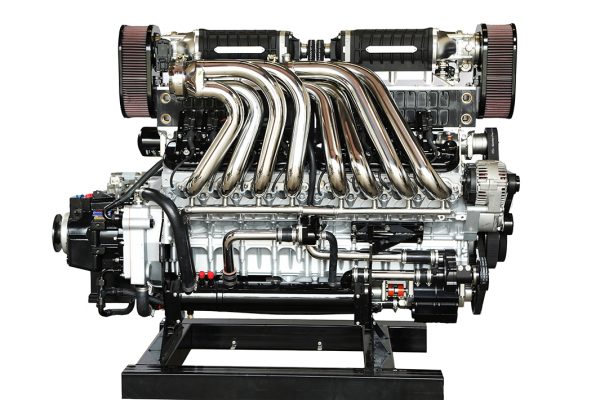

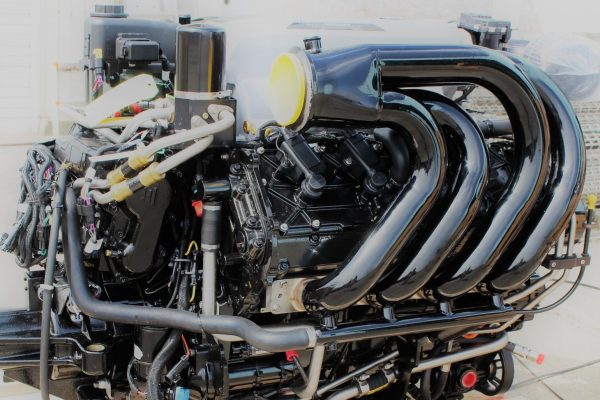

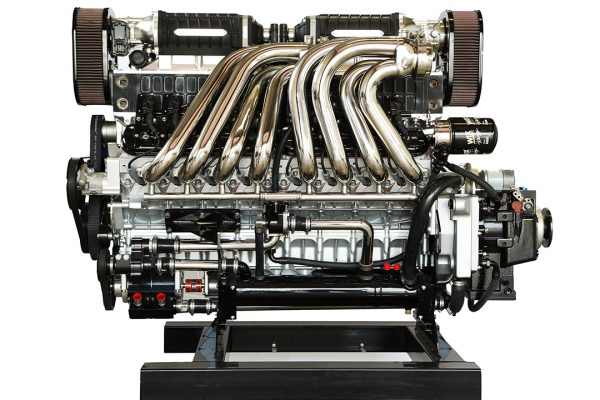

We will take your project to the next level by integrating hydraulics, position sensors, optical solid state switching, paint, plating and polishing too. We will take on your new project with a CAD model, but we can also take your napkin sketch from concept to an innovation award.

We don’t just machine it, bend it and weld it, at Custom Marine.

From startups to iconic brands, we have engineering resources for you. Take a look at the slider below to see some of our past and current projects

Work with Custom Marine

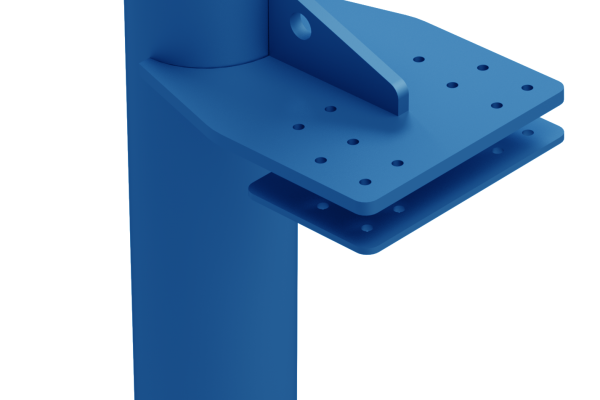

Each of our three manufacturing locations works together to provide components to the location where your custom part will be assembled. Aluminum and stainless welding, forming, and bending meet up with parts that are milled or turned at our sister facilities to expedite the manufacturing process. Some unique in-house resources include an automated wire harness department, plating, paint, powder coat, polyurethane molding, laser engraving and electropolishing.

Dock to stock is what’s expected if it arrives in a CMI box. Each of our ISO certified locations has the quality equipment and personnel to ensure your parts arrive manufactured to print.